Waste-to-Fuel & Hydrogen Burners — Scalable Industrial Solutions

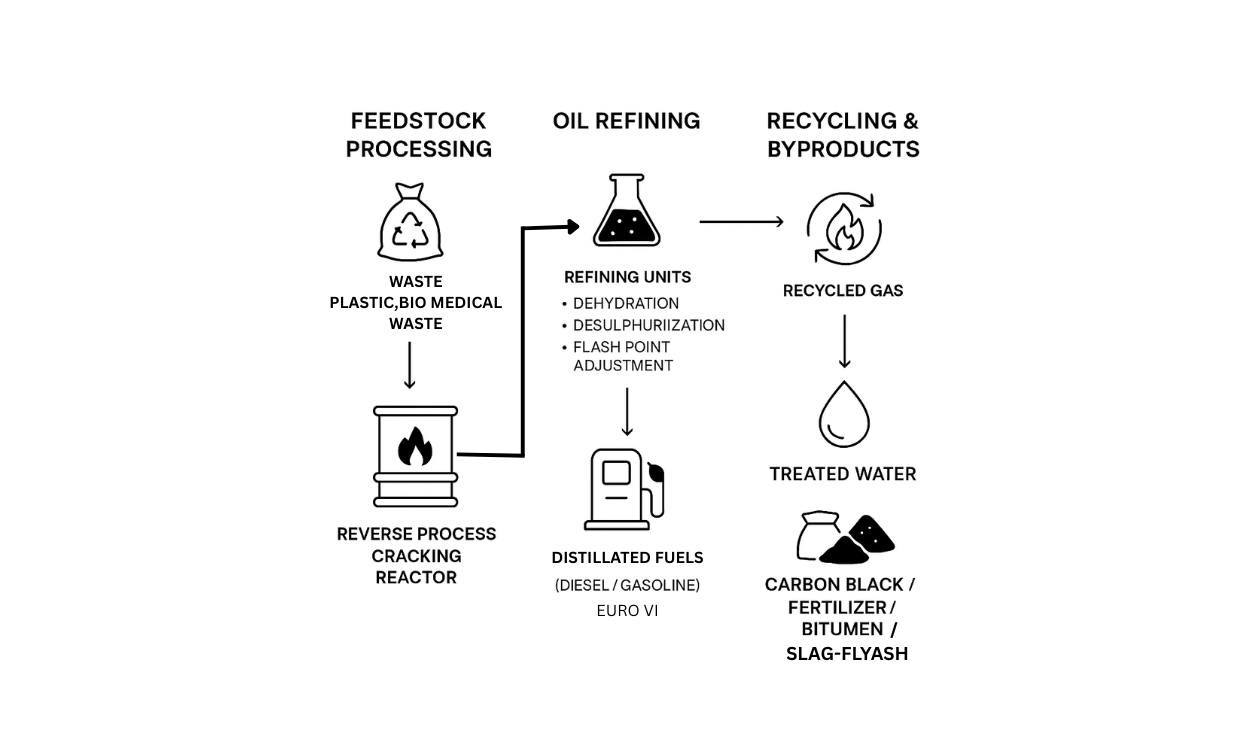

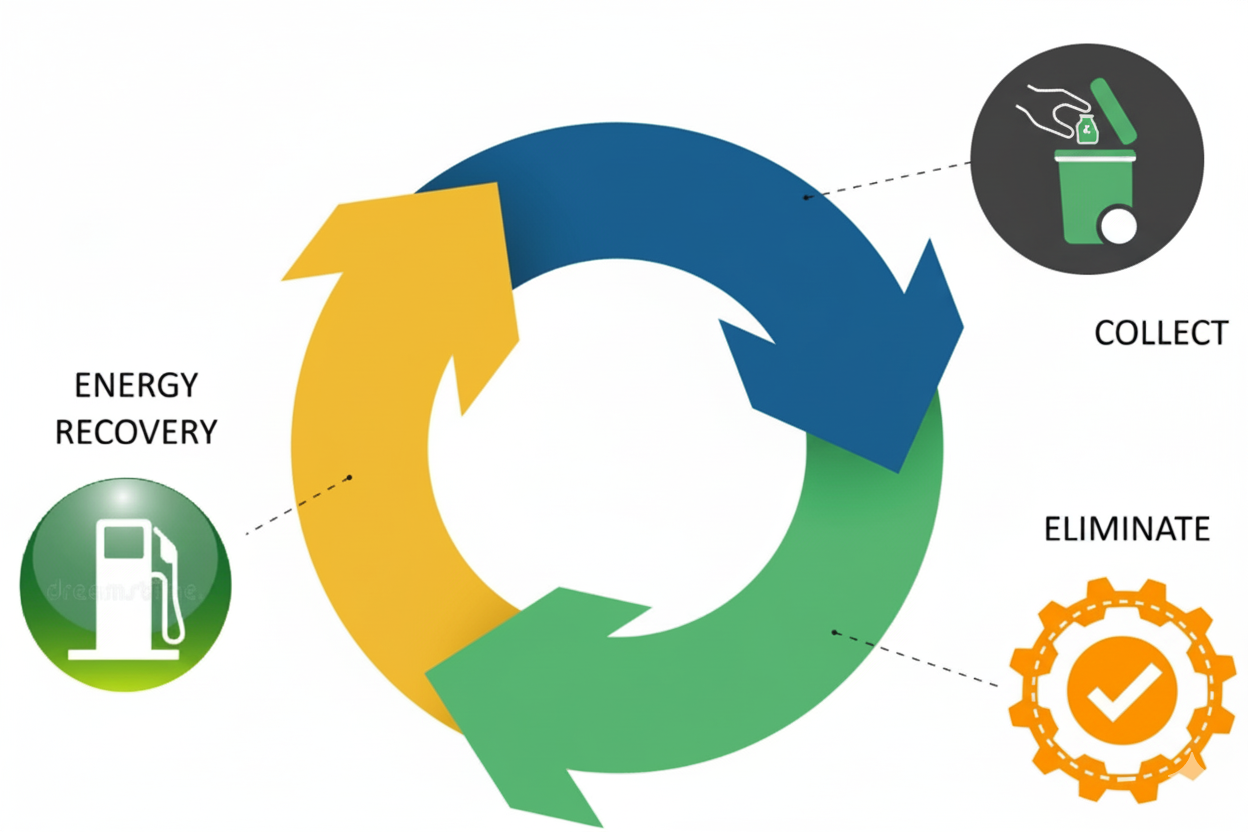

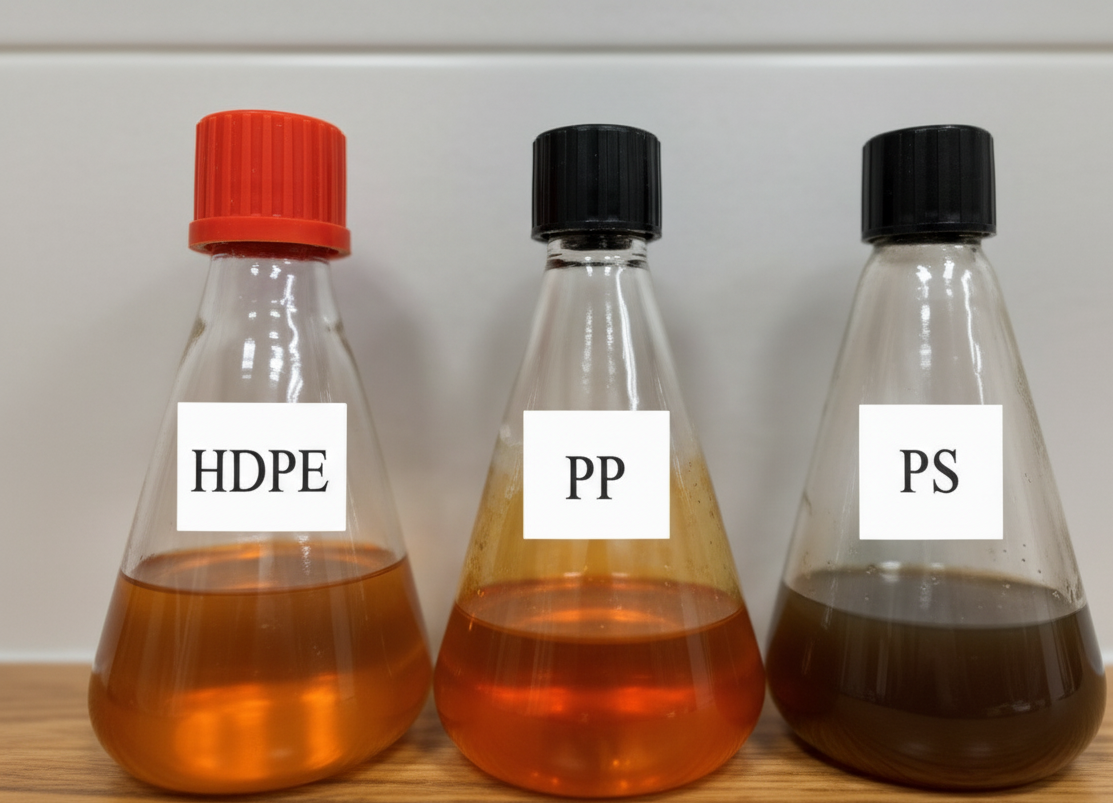

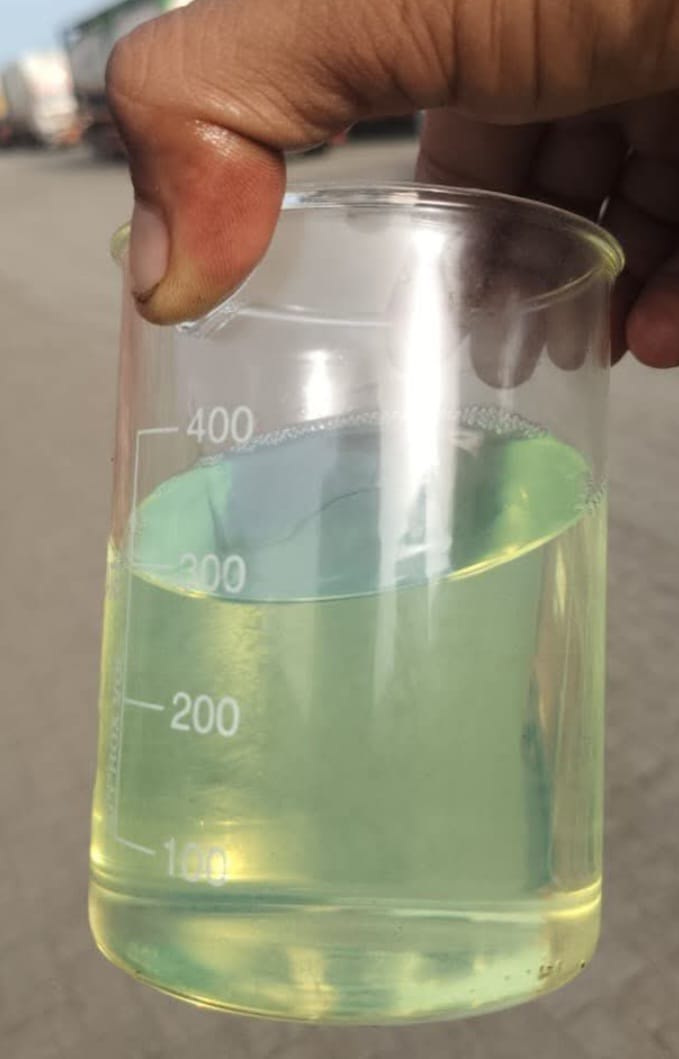

Continuous, automated Green Reverse Pyrolysis converting MSW, plastics and tyre waste into Euro IV–grade fuels, hydrogen, and construction-grade by-products — with emissions control and safety systems.